How high the bar is set for quality requirements in the automotive industry?

August 09,2019Last week, Bergstrom carried out an 8D training workshop for some suppliers to provide some guidance on the problem-solving process and techniques for vehicle systems.

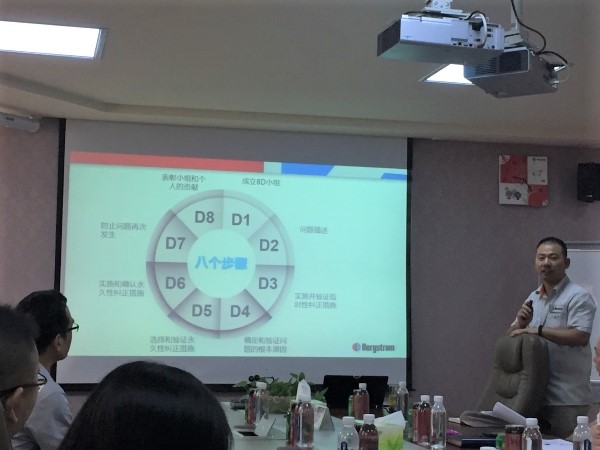

We invited experienced quality control and process control personnel to deliver the training. During the workshop, they discussed how to improve problem-solving ability and internal processes with the emphasis on the application of the 8D method in daily management.

The eight disciplines (8D) model is a problem-solving approach aiming at quality improvement first developed by Ford Motor Company in 1987. After continuous modifications and improvement made by the members of Ford’s vehicle system team, the 8D method has become a major component of the TS16949, later called IATF 16949 (International Automotive Task Force) quality standards.

8D is also known as Team Oriented Problem Solving (TOPS). The goals of this method are to find the root cause of a problem, devise a short-term fix and implement a long-term solution to prevent recurring problems.

As one of the most effective approaches to solving quality problems, 8D is commonly used by the global automotive industry, especially by the mainstream vehicle parts manufacturers.